Haomei aluminum > Haomei News > Cold rolled & hot rolled 1070 aluminum circle

Cold rolled & hot rolled 1070 aluminum circle

Writer:Admin Time:

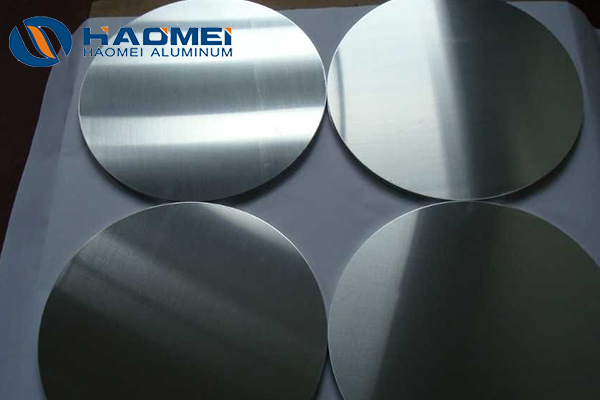

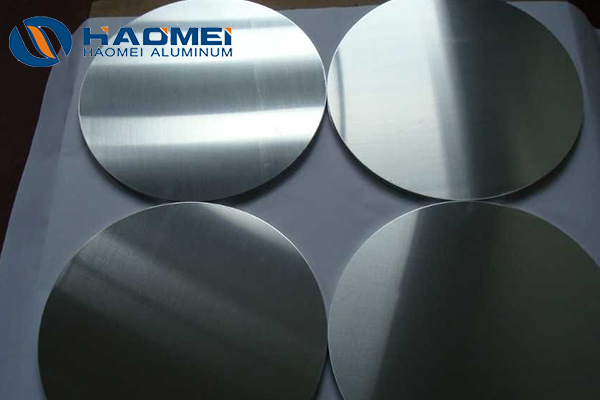

The cold rolled & hot rolled 1070 aluminum circle actually refers to at least two kinds of aluminum circles. Hot rolling is hot working, and rolling is performed above the crystallization temperature. Cold rolling is cold working, and rolling is performed below the crystallization temperature. The residual stress distribution of cold-rolled aluminum section is curved, and the residual stress distribution of hot-rolled aluminum section is thin film.

Cold rolled 1070 aluminum circle can be made fast, and does not damage the coating. It can be made into a variety of cross-sections to meet the needs of the use conditions; cold rolling can cause aluminum to have a large plastic deformation, thereby improving yield point of the circle. Hot rolling can destroy the casting structure of aluminum ingots, refine the grains of aluminum materials, and eliminate defects of microstructures such as air bubbles, cracks and looseness, so as to make the 1070 aluminum disc structure dense and improve mechanical properties.

Haomei supplies both hot rolled and cold rolled 1070 aluminum circles of 0.5mm to 6mm thick. Diameter ranges from 100mm to 1200mm. In addition to mill finish circles, we also supply anodized and coated ones. The circles are mostly used in cookware, pressure tanks, lamp parts etc. We boast a huge client date base covering over 70 countries, and you will never need to worry about our familiarity with your market.