Haomei aluminum > Haomei News > Growth Of Aluminum Foil And Packaging Market

Growth Of Aluminum Foil And Packaging Market

Writer:Admin Time:

Food Preparation: Aluminum foil is “dual-ovenable” and can be used in both convection and fan-assisted ovens. A popular use of foil is to cover thinner sections of poultry and meat to prevent overcooking. The USDA also provides recommendations on limited uses of aluminum foil in microwave ovens.

Insulation: Aluminum foil is 88 percent reflective and is widely used for thermal insulation, heat exchanges and cable liners. Foil-backed building insulation not only reflects heat, aluminum sheet also provides a protective vapor barrier.

Electronics: Foil in electrical capacitors provides compact storage for electric charges. If the foil surface is treated, the oxide coating works as an insulator. Aluminum foil capacitors are commonly found in electrical equipment, including television sets and computers.

Geochemical Sampling: Aluminum foil is used by geochemists to protect rock samples. Foil provides a seal from organic solvents and does not taint the samples as they are transported from the field to the lab.

Art and Decoration: Anodizing aluminum foil creates an oxide layer on the aluminum surface that can accept colored dyes or metallic salts. Through this technique, aluminum is used to create inexpensive, brightly colored foils.

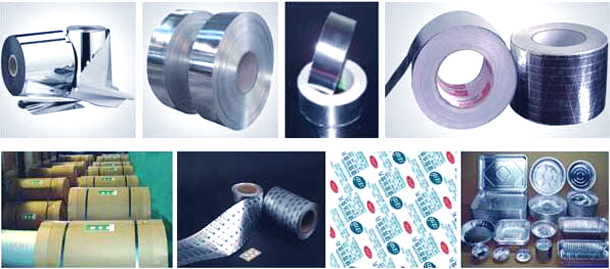

The aluminum foil sheet thick using has a long history and widely used in many fields.

The origin of aluminum foil can be traced by to the early 1900s. Life Savers—one of today’s most popular candies—were first packaged in foil in 1913. To this day, the treats are encased in the world-famous aluminum foil tube. The uses of foil have grown over the past 100 years to a nearly endless count. From Christmas tree ornaments to spacecraft insulation, TV dinners to medicine packets—aluminum foil has, in many ways, improved both our products and our lives.

One of the first commercial uses of aluminum foil came in 1913. Foil leg bands were used to identify racing pigeons.

Released in 1959, combined a heavy-gauge foil pan and an expandable, light-gauge foil cover to deliver their “magic treat.”

Effective for energy conservation

The “shiny” side of aluminum foil is 88 percent reflective, making it one of the best and most efficient insulators to solar heat.

Billions of containers are produced each year

Approximately 7 billion aluminum foil containers are produced annually. This production rate nets to 220 containers produced every second.

The first pre-formed, all-foil food packaging containers appeared on the market in 1948. This grew into the complete line of die-formed and air-formed foil containers now sold in every supermarket. A spectacular period of growth occurred in the 1950s and 1960s. TV dinners, packed in compartmental trays, began to reshape the food products market. Packaging foil is now divided into three major categories: household aluminum foil sheet, semi-rigid foil containers and flexible packaging. For decades, the use of foil has grown steadily in each of these categories.

The resourses is from Haomei Industrial Co., Ltd. Any requist and question please contact our Email:august@haomei-aluminium.com

The resourses is from Haomei Industrial Co., Ltd. Any requist and question please contact our Email:august@haomei-aluminium.com