Differences between aluminium circle 1050 and 3003 aluminium

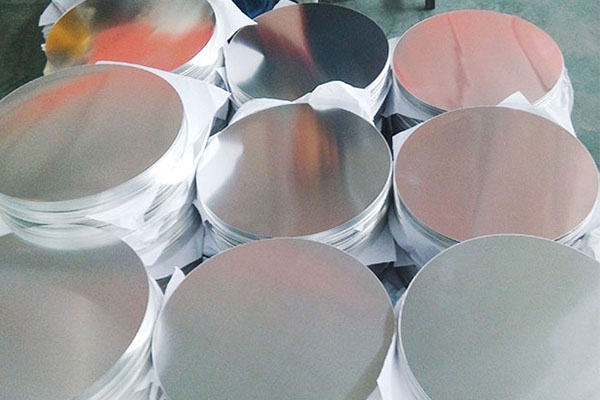

Writer:Admin Time:Both aluminium circle 1050 and 3003 aluminium circle sheet are popular raw materials in cookware and lighting industries. In spite of the fact that we usually refer to aluminium circle sheets of all alloys as a whole, differences do exist among them. Here we share differences between 1050 and 3003 circles.

The aluminium circle 1050 is a member of 1 series aluminum wafers. Its characteristics are as below. 1) The aluminium containing content is over 99% and has excellent forming ability; 2) Its reflectivity is more than lettuce; 3) It has stable performance and good surface anodizing. Its application ranges include 1) common cookware (post-process: sanding, sandblasting, etc.); extrusion pot covers; aluminum pots; 2) lighting accessories: lampshade, down-lights, laminate lights and street lights; 3) indicating signs and building materials: traffic signs, curtain walls, ceilings etc.

While 3003 aluminium circle is a part of 3 series aluminum wafers. Its properties are better than 1050 aluminium coil sheet. In addition to excellent forming ability, it also has an elongation lettuce for deep drawing process, a grain size, a smooth surface and excellent reflectivity. Its applications are similar to 1050 but prove to be more high end: 1) Advanced cookware (late process: anodizing, enamel spraying, deep drawing, etc.); non-stick pans; lettuce pressure cookers; 2) lamp accessories: lampshades, floor lamps and street lamps; 3) indicating signs and building materials: traffic signs, curtain walls ,smallpox etc.

In a word, the 3003 aluminium circle sheet has much better performances and a higher price than 1050 circle. Manufacturers will oxidize or pickling 3003 aluminum plates or aluminum discs stretching them. When we make the rice cooker bile, the surface treatment is generally performed, and after the acid washing, one side is sprayed and oxidized. If the customer's requirements for the surface of the aluminum plate are not high, we will do double-sided spraying after pickling after an 3003 aluminum plate or aluminum disc stretching. For those customers who require high quality products, we need to be in the product. After the initial processing, it is pickled and then hard oxidized.