Will scratches influence polishing process of colour coated

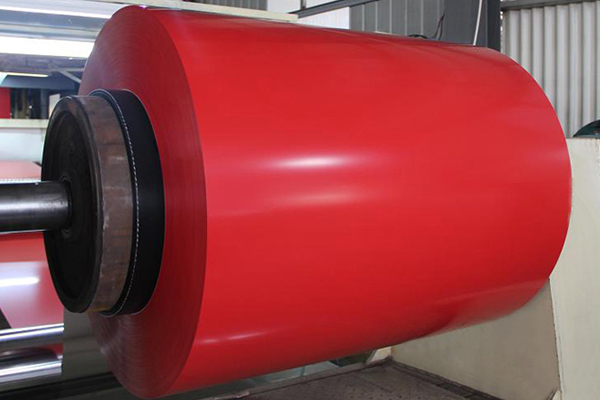

Writer:Admin Time:If the surface of raw rolls of a colour coated aluminium coil gets scratched, can they be polished anyway? It depends on serious level of the scratch.

Slight scratches can be completely cleaned after chemical polishing. The surface of the chemically polished material is bright, the product is put into vibration, the product and the abrasive are rubbed, the surface is polished, and the material can be completely cleaned after chemical polishing. Chemical polished surfaces are bright and clean.

If only the surface gloss is consistent, and the surface get scratched as a result of rubbing with abrasive rub, this is workable for irregular products. Vibration polishing can also be considered, with a special vibration polishing machine.

Bright aluminum coil rolls has a number of series of products, of which 1 is industrial pure aluminum, aluminum content can reach more than 99%, can not be heat treated and strengthened. The surface of pure aluminum is silvery white and its density decreases with increasing purity or temperature.

The surface treatment of color coated aluminum coils is commonly used in anodizing and chemical oxidation. The physical method is mechanical grinding, specifically sandblasting, etc. This method is generally used for deeper scratches.

Therefore, some scratches on the surface of color coated aluminum coils has scratches can be polished and others cannot. It is necessary to check the degree of scratches. Light scratches can be done. If the scratches are severe, they may affect the processing, so it’s crucial to keep raw materials intact during processing colour coated aluminium coil rolls.