Color Coated Aluminum Coil Coating Process

Writer:Admin Time:

The coating process is the most critical step in the production of color coated aluminum coil, which directly affects the final coating quality and the durability of the product. Therefore, the coating process is more stringent.

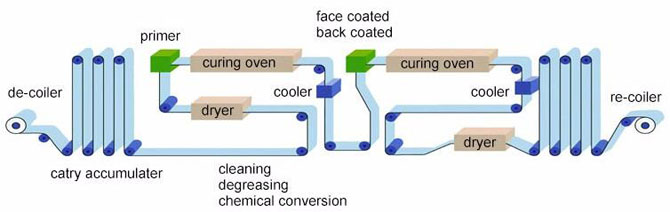

General production technology of coil coating has five steps, namely the aluminum coil type, cleaning and chemical treatment, paint, curing and finished product output.Different conditions of different process arrangement and equipment composition, but the basic parts are the same.

First, the volume of raw material input, is to open-book machine to ensure continuous continuous volume open-book production line with a stable input, and some take the cross beam beam loader, but also to take two sets of alternating decoiler before and after, in short, in order to timely volume;

Second, the surface cleaning and chemical treatment, is to make the upper and lower aluminum surface must be cleaned, the chemical pretreatment, in order to ensure that the paint can be firmly attached;

Third, paint, a production line at least two or more roller coating machine, to ensure that the two-tier paint finish and primer;

Fourth, the paint layer curing, refers to the just-painted coil to contact the next roller in a fixed before the completion of the words, to avoid mutual adhesion and damage, in general, contains at least two curing box;

Fifth, the finished product output to ensure that the production line speed and finished volume transfer synchronization.

Color coated alumium coil processing, widely used in construction, electronic appliances, furniture, solar reflectors and so has a wide range of applications.Freely contact us Email:august@haomei-aluminium.com