Aluminum tubing coil|aluminum coil stock suppliers

Writer:Admin Time:

Aluminum tubing coils widely used for the air conditioner, refrigerator and garage fuel line, so its mechanical properties are very important in the actual application.

In the oil and gas industries,Aluminum coil tubing refers to a very long metal pipe,normally 1 to 3.25 in (25 to 83mm) in diameter which is supplied spooled on a large reel.It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas well.

aluminum tubing is suitable for nitrous, fuel, and water lines and is available in 25' coils. The tubing is easy to work 3003 aluminum with a .035" wall thickness (20 gauge). For end installation simply flare with Fragola's 37 degree flaring tool and install an AN (FRA5818) Tube Nut with an AN (FRA5819) Tube Sleeve.

Tensile strength: > 70Mpa

Elongation: >30%

Yield strength: >68Mpa

Pipe inside cleanness: <30mg/m2

Water content:<0.02mg/m2

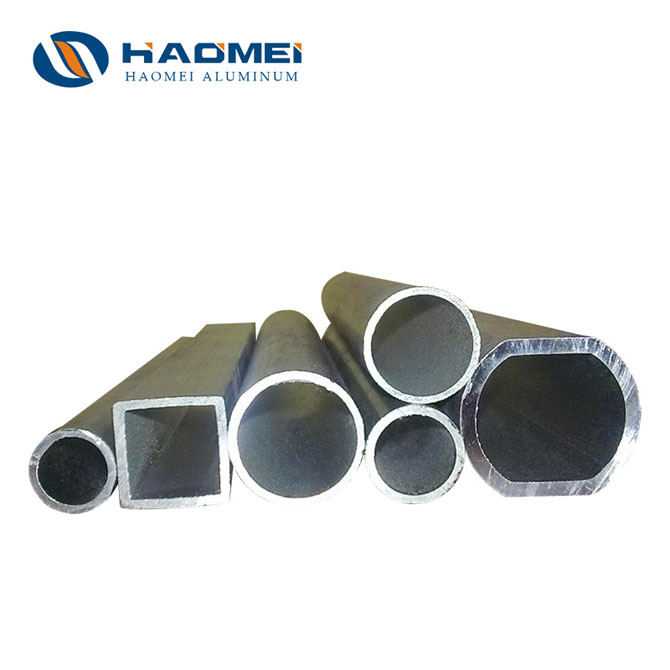

There are two types of aluminum tubong coil:

1.aluminum extruted coil tubing:aluminum extruted coil tubing formed by hot extruding through a die,it is avaliable as a seamless or structural grade product.

For extruded aluminum tube OD from 5mm to 25mm and wall thickness from 0.5mm to 1.5mm. For Air conditioning pipe often use 1/4″, 3/8″,1/2″, 5/8″ and 3/4″ air conditioning piping. For refrigerator often use 5mm, 7mm, 9.52mm, 8mm, and 10mm etc

2.aluminum drawn coil tubing:aluminum drawn coil tubing is a seamless extruded coiled tubinh is brought to final size by drawing through a die.

Working with drawn aluminium tubes one had two choices:

Tubes in coils (or length), drawn from porthole extruded material and mainly limited to soft alloys like EN-AW3003 or EN-AW3103.

Tubes from seamless or mandrel extruded material and hard alloys but only available in length of up to 6-7m.

The new development combines a particular form in supply of pre-material with a special connecting technic to achieve a strong connection surviving the coiling, re-drawing, de-coiling and straightening on a conventional cutting machine. This connection is still open for gas to run through the whole coil thus allowing the necessary flush during an annealing process.

The great advantage lies in the reduction of the cutting scrap by 10-20% depending on the range of cut length. Besides this usage it also delivers tube length of 100-300m of seamless aluminium tubes for applications in the chemical or gas processing industry.